Latest News

Successful Installation of new Twin Wire Press at Cheney DYNOS Inc.

After 2 years of preparation, the Twin Wire Press, designed by Press Technologies and installed with the support of Fenton, was installed during the planned Maintenance Shut Down and placed in operation on July 22nd, 2024.

“This was the largest project for Cheney Dynos Inc. in the past years,” said the Managing Director of Cheney Dynos Inc., Michelle Sears, “it makes me very proud, that we were able to complete it within the timeline and – what is even more important for me – without any safety incidents.”

“The Twin Wire Press is one of the Key Equipment to produce high-quality pulp and paper. Replacing it, is a further milestone to improve and modernize this Facility. Congratulations to the team for realizing this project according to schedule and budget.” As quoted by Dr. Florian Kaletta, COO of the DYNOS Group.

Travis Allen (Operations Manager), Michelle Sears (Managing Director).

New Managing Director, Cheney DYNOS Inc, Franklin

We are pleased to announce that Michelle Sears will be joining Cheney Dynos, Inc. as Managing Director.

Michelle will take over the management of the Cheney DYNOS plant from April 9, 2024. Michelle has a strong background in Engineering and more than 20 years’ experience in Manufacturing. DYNOS is looking forward for continuing our good work together with the further strengthened site management team at CDI.

The Troisdorf location of the DYNOS Group expands its capacities

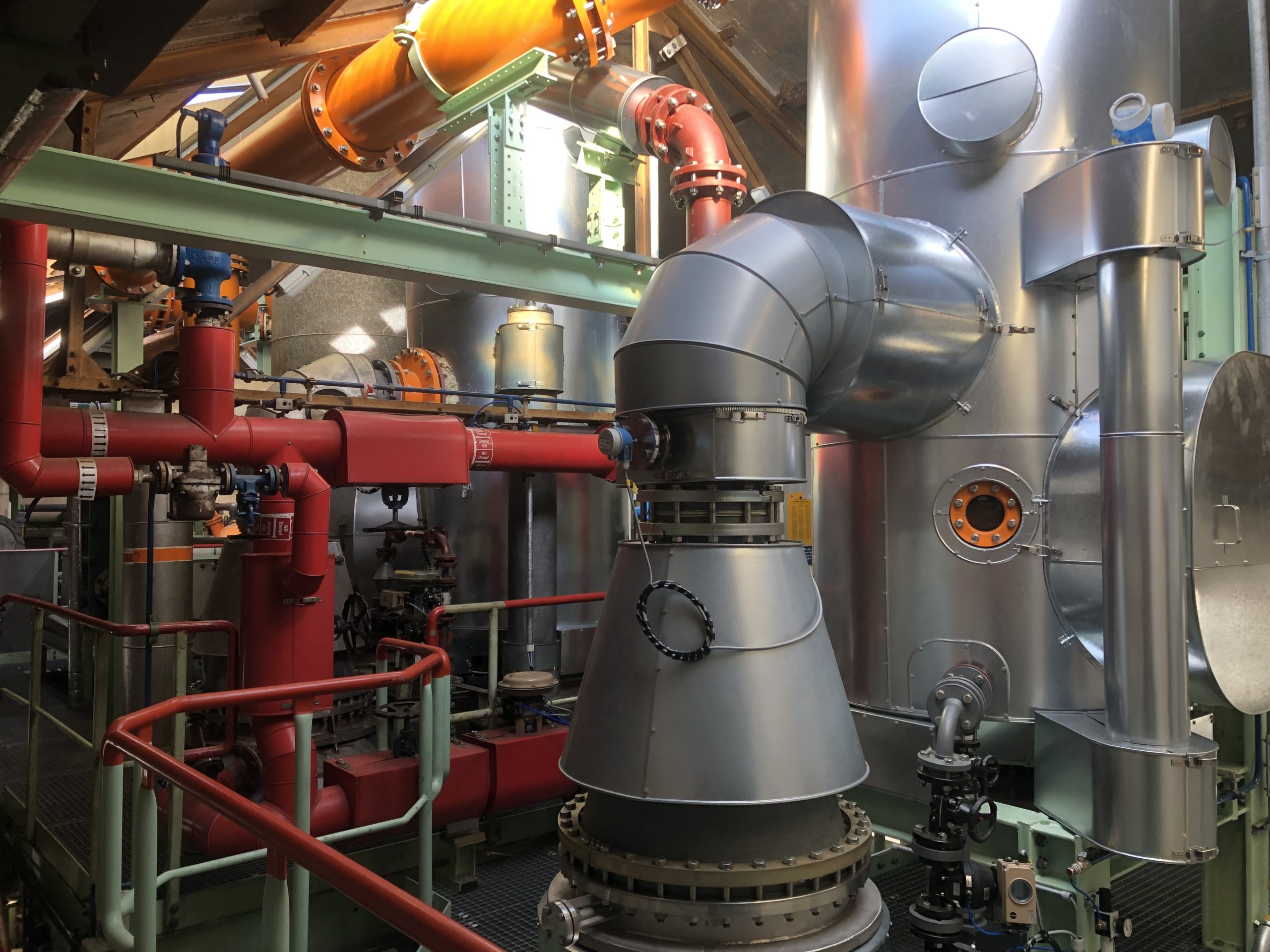

The capacity expansion of the vulcanised fibre plant in Troisdorf, near Bonn, was placed into operation on 2022 August, 22nd.

The third vaporization stage of the evaporation plant, designed and implemented by EBNER from Eiterfeld, Germany, ensures a significant increase in productivity for the overall output and thus enables an improved supply to our customers.

By using modern 3D planning technology, the tight space conditions could be optimally used and possible conflicts with other existing plant components avoided.

The state-of-the-art PCS (Process Control System) installed guarantees ideal usage and monitoring of the new plant, now by two PC screens instead of switchboards.

"A big kudos is owed to all those involved," said Project Manager of the Troisdorf location, Mr. Michael Skirke, "within the given short timeframe in cooperation with Ebner, the plant could be pre-installed during ongoing production, and put into operation during the planed summer shut-down. Thanks to the improved technology, the machine operators did not have any problems running in the plant.

Despite these challenging conditions, we were able to eliminate any risk of injury or accident, which is not a matter of course!"

"By expanding our capacity, we are taking a further step toward securing our market leadership. On behalf of the management board, I would like to expressly thank all those involved in the project. They have managed to adhere to the challenging schedule and the agreed budget." As quoted by Dr. Hans-Peter Koller, CEO and Owner of the DYNOS Group.

The DYNOS Group is expanding

The DYNOS Group takes over Cheney Pulp & Paper USA.

Effective the 12th of August, 2022 DYNOS assumed ownership of the assets of the “Cheney Pulp & Paper” company, located in Franklin, Ohio, USA. The newly formed entity Cheney DYNOS INC. manufactures pulp from textile wastes and cotton products, which are then used for making technical paper, on an industrial scale and in high quality. With this acquisition, DYNOS secures its first stage of production in the manufacture of vulcanized fibre. The company “Cheney Pulp & Paper” was an owner-operated company, respected in the industry for generations. Their operations are now taking on an important strategic place within the DYNOS Group.

“With this investment, we were able to take an important step in the improvement of our overall effectiveness and economic efficiency,” said Dr. Hans-Peter Koller, CEO of the DYNOS Group. “Along with securing its base product for vulcanized fibre, Cheney DYNOS is able to cover other product categories for third-party customers. This gives us diversification and with it, broader support in the market of processed raw and recycled cotton fibres.” By processing the wastes from the textile industry, Cheney DYNOS also makes a significant contribution to the environmental sustainability of products.

New company and new location

The DYNOS Group is restructuring its locations and sustainably expanding its leading market position as a supplier of Vulcanized Fibre, Pulp, and Speciality Paper.

With the acquisition of the major assets of the US manufacturer Cheney Pulp and Paper, the Group has secured an important player for the processing of plant fibres on the international market.

In the process of the global realignment, the production of rags (processing of used cotton textiles) and linters in Bad Duerkheim has been ceased. With active staff transfers, a redundancy programme and the formation of a transfer company, the DYNOS Group is making the transition amicable and socially compatible. After the takeover from the insolvency of Cordier Spezialpapier with the prevailing very demanding circumstances as per September 2020, a sustainable economic perspective for the pulp production at this location, especially as intensified by the strongly increased procurement and energy costs, was no longer feasible. The management would like to thank all those involved for their great personal commitment.

Cheney has been active in the pulp and specialty paper market for over 75 years. The site in the US state of Ohio will assume a central function in the supply of raw materials for the DYNOS Group. Cheney's unique experience in rag manufacturing, their high efficiency and cost leadership as well as their excellent customer contacts will strengthen the DYNOS Group in the long term. Hence, DYNOS secures, in particular, the added value of its successful products from its own resources. As supply chains and logistics will continue to remain challenging in the near future, an intelligent and future-oriented location policy is of utmost importance: this is what drives the DYNOS management.

For a world with less plastic and

more natural materials

Natural fibre pulp and sustainable paper are increasingly in demand. In the course of the transformation towards sustainable processes and products, industry is intensively searching for alternative materials. DYNOS Pulp, DYNOS Vulcanized Fibre and other specialty papers, obtained from recycled materials, are playing an increasing role in this process; and this for very different applications: from abrasives to recycled yarns for the clothing industry to special solutions made from paper and vulcanized fibre. In laboratories around the world, further applications for pulp and paper are being sought as replacements for previous plastic solutions. We will keep you up to date.