Bioplastics are the future

Industry is undergoing a major transformation towards sustainability: To a world with less plastic and more natural materials. Bioplastics made from bio-based raw materials play a major role in this transformation. DYNOS makes an important contribution in this respect. Vulcanized fibre of DYNOS quality is a bioplastic made from recycled materials – it represents an optimal alternative material for a wide range of applications and opens up sustainable prospects for success for industry.

Vulcanized fibre –

pioneer of bioplastics

Vulcanized fibre is the oldest bioplastic in the world. The discovery of vulcanized fibre in the mid-nineteenth century provided the initial impetus for the development of sustainable bioplastics. Nowadays, our manufacturing method for the bioplastic vulcanized fibre sets the standard – DYNOS is the world's leading manufacturer.

The bioplastic vulcanized fibre consists of pure cellulose, i.e. a matrix of partially dissolved regenerated fibres reinforced by undissolved cellulose fibres. This results in a unique property profile that is optimal for a wide range of industrial applications. The combination of high mechanical strength and low specific weight means that vulcanised fibre is ideal as a carrier material for grinding discs or as a component in lightweight construction. Vulcanized fibre is not easily flammable and has a high insulating effect – ideal properties for mechanical and plant engineering as well as electrical engineering. A landmark of biomaterial vulcanised fibre is its versatile opportunities of processibility, such as chipping, forming and surface finishing.

The disposal of the bioplastic vulcanized fibre is not harmful for the environment as it is degradable under composting conditions. In other words, vulcanized fibre is the material of choice for a sustainable economy.

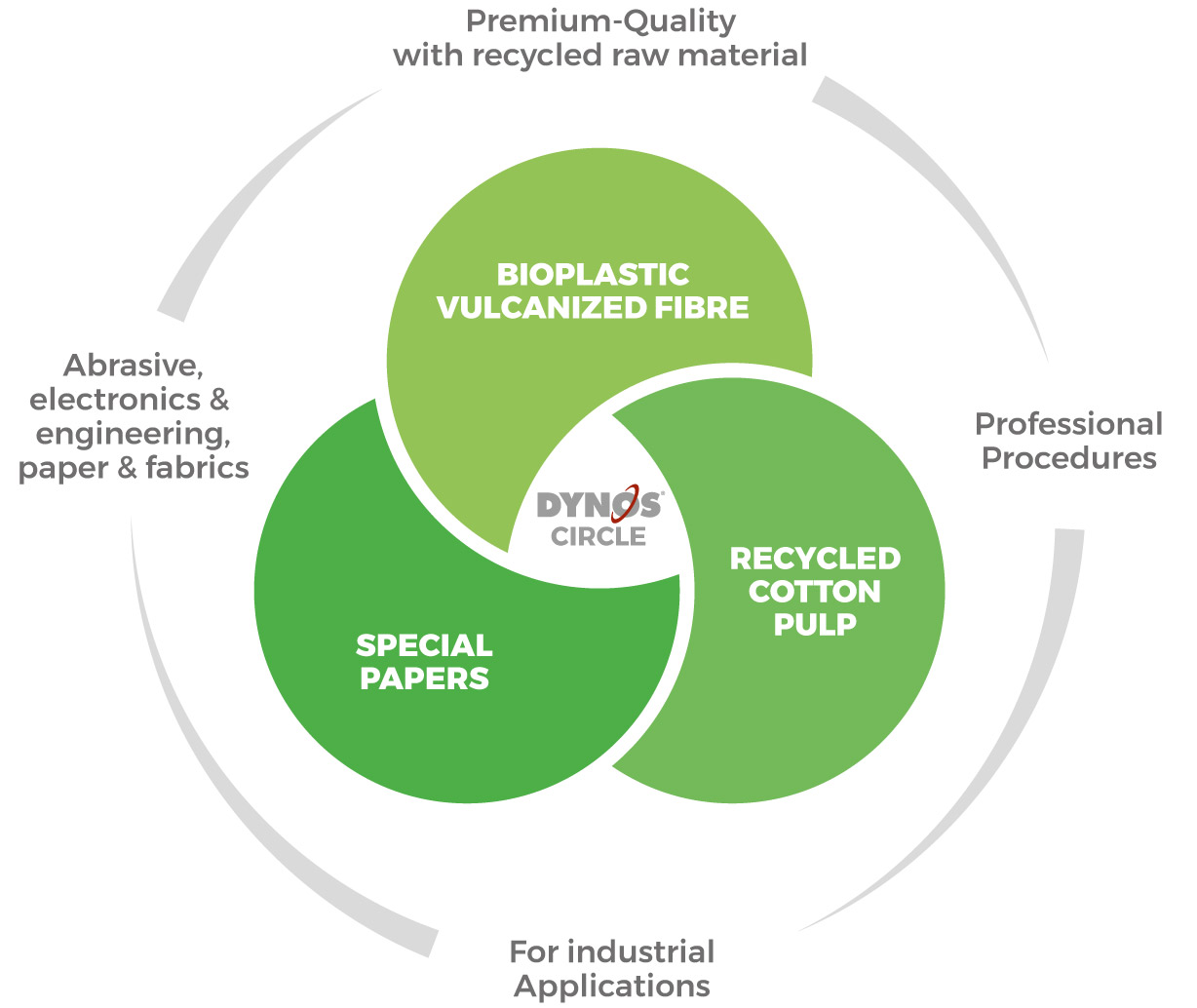

The DYNOS CIRCLE

DYNOS incorporates sustainability into every part of its value chain: our processes are ecologically certified and subjected to strict audits. This is borne out by numerous certificates which, taken together, give rise to a closed green cycle: from recycled raw materials and professional processing to bio-based base materials for industry. This is the unique DYNOS Circle. Sending a message to our industrial partners worldwide: DYNOS manages all stages of its value chain – DYNOS supplies everything from a single source.

Acting in cycles

The ability to work in cycles is one of the central requirements for industry in the 21st century. DYNOS has always fulfilled this requirement. The entire product portfolio of the DYNOS Group is based on natural and recycled materials.

We recycle textile clips and post-consumer paper from the reusable material cycle and convert them into a state-of-the-art industrial product.

During the production of vulcanized fibre, we take special care to implement environmentally friendly and resource- efficient processes in our day-to-day activities. We utilize textile cotton clips along the integrated value chain – right down to the ultimate finishing step consisting of the chemically induced catalysis of cotton fibre yielding vulcanized fibre. We use zinc chloride as a catalytic parchmentizing agent - which we fully recover in the closed production loop. Engineering expertise and responsibility: typically DYNOS.

Moreover, even waste can be rendered useful once again by DYNOS know-how: our engineering teams developed a new material from cotton dust – cotton paper. Cycle economy – perfectly mastered by DYNOS. And by doing so, we have contributed to making industrial production more environmentally friendly and sustainable.

Sustainability is our middle name

Sustainable economy on an industrial scale – that is the DNA of DYNOS. Our raw materials have always been drawn from recycled materials. We work in closed cycles and monitor all production steps professionally and environmentally sound. In doing so, we are independently audited and certified.

Finally bioplastics are generated setting standards especially dedicated to quality, versatility and sustainability. In this way, DYNOS opens up the best possible prospects for many industrial sectors, enabling them to attain their own sustainability goals. With materials that close cycles, preserve natural resources and ensure good balance sheets: both economically and ecologically. In balance with nature – the DYNOS way.

Im Kreislauf handeln

Speziell in der Vulkanfiberproduktion achten wir besonders auf umweltfreundliche und ressourcenschonende Verfahren. Als katalytisches Pergamentiermittel verwenden wir Zinkchlorid – das gewinnen wir im geschlossenen Fertigungskreislauf vollständig zurück. Ingenieurskunst und Verantwortung, typisch DYNOS.

Der Dynos Circle

DYNOS kann an jedem Punkt seiner Wertschöpfung nachhaltige Akzente setzen: unsere Verfahren sind ökologisch zertifiziert und unterliegen strengen Audits. Zahlreiche Zertifikate belegen das und bilden zusammen einen geschlossenen, grünen Kreislauf, wir nennen es den DYNOS Circle. Hier eine Liste der aktuellen Zertifizierungen in unseren Produktsparten:

DYNOS Pulp

GRS / Energiemanagement nach DIN EN ISO 50001

DYNOS Paper

Blauer Engel / FSC / Energiemanagement nach DIN EN ISO 50001

DYNOS Fibres

DIN EN ISO 9001 Standard / UL (Underwriter Laboratories) / Energieaudit DIN EN 16247

Wasser & Energie – Sauber

Bei unseren Prozessen benötigen wir Wasser – wir nutzen es und reinigen es professionell und umweltgerecht in unseren eigenen Kläranlagen. Diese werden laufend unabhängig geprüft und zertifiziert. Für die Energieversorgung an unseren Standorten nutzen wir verstärkt Strom aus regenerativen Quellen. Schritt für Schritt reduzieren wir unseren CO₂-Ausstoß, unsere Vision ist die klimaneutrale Produktion innerhalb der DYNOS Gruppe.